Subcategories

NEW PRODUCTS FOR FEBRUARY - S-3 AIRLESS SPRAY GUN

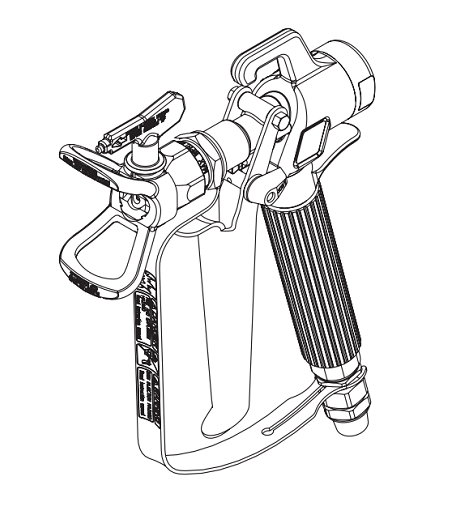

For professional painters and contractors who demand accuracy, robustness, and efficiency, the S-3 Airless Spray Gun is a high-performance instrument. By atomizing paint without the need of compressed air, this spray gun minimizes overspray and increases transfer efficiency, resulting in a perfect finish. The S-3 Airless Spray Gun guarantees a smooth and even finish with little effort, whether it is used for commercial, residential, or industrial painting tasks.

The S-3 Airless Spray Gun Parts List is crucial for anyone wishing to maintain or fix their spray gun. Key parts that guarantee optimum performance are included in this list, including spray tips, filters, trigger assemblies, and seals. Your spray gun's lifespan and efficiency can be increased with routine maintenance and high-quality replacement parts.

Visit AllTitanParts.com to view a complete S-3 Airless Spray Gun components List or to get replacement components. Genuine parts are available on our website, guaranteeing compatibility and enduring performance. We make it simple to maintain the best possible condition for your S-3 Airless Spray Gun with our wide variety and knowledgeable assistance. Place your order right now to keep your spray gun dependable and of high quality for all of your projects.

The S-3 Airless Spray Gun is a precision-engineered, high-pressure spray gun designed for professional coating applications where consistent atomization, durability, and operator control are critical. Built with a rugged metal body and wear-resistant internal components, the S-3 gun delivers stable spray patterns across a wide range of coating materials, including latex paints, primers, enamels, industrial coatings, and protective finishes.

The gun features a high-flow fluid passage design, optimized trigger mechanism, and stainless-steel needle/seat assembly to reduce pressure drop, minimize pulsation, and improve coating transfer efficiency. The ergonomic handle and balanced weight distribution help reduce operator fatigue during extended spray cycles, while the integrated safety trigger lock supports secure handling in demanding jobsite environments.

Engineered for compatibility with professional airless sprayers, the S-3 Airless Spray Gun provides reliable performance in residential, commercial, and industrial coating applications.

The S-3 Airless Spray Gun is suitable for:

The S-3 gun is engineered for high-pressure airless systems, supporting typical contractor-grade operating pressures used in professional spraying applications.

It supports latex, acrylics, oil-based coatings, primers, enamels, protective finishes, and select industrial coatings, depending on material viscosity and tip selection.

Inspection is recommended after heavy usage cycles or when performance symptoms appear, such as leakage, inconsistent spray pattern, or reduced pressure.

Yes the S-3 gun is designed with replaceable service parts, including the needle, seat, springs, seals, and trigger components, allowing extended operational life.

Always fully depressurize the sprayer, disconnect the fluid supply, and follow manufacturer safety procedures before disassembly or servicing.