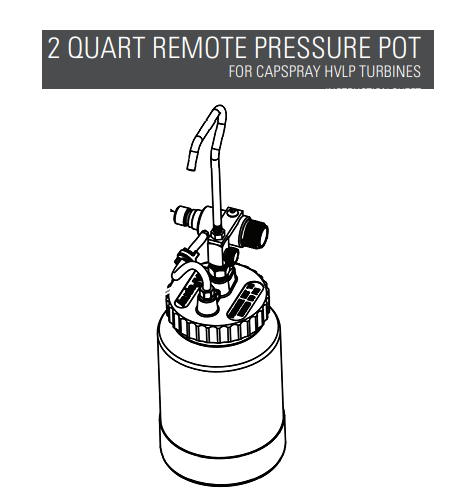

NEW PRODUCTS FOR FEBRUARY - 2 QUART REMOTE PRESSURE POT FOR CAPSPRAY HVLP TURBINES

For experts looking for a longer spray time and steady paint flow, the 2-quart remote pressure pot for capspray HVLP turbines is a necessary addition. This remote pressure pot's greater paint capacity and seamless integration with Capspray HVLP turbine systems minimize the need for frequent refilling. It is perfect for large-scale projects that need uninterrupted, continuous spraying because it guarantees a consistent and level paint supply.

Having access to the 2 Quart Remote Pressure Pot for Capspray HVLP Turbines Parts List is essential to maintaining the proper operation of your system. This list contains essential parts that guarantee lifespan and optimum performance, such as fittings, hoses, pressure regulators, and seals. Maintaining your equipment on a regular basis using high-quality replacement parts helps to avoid downtime and keeps it in optimal shape.

Go to AllTitanParts.com to find authentic replacement parts and accessories. To maintain and improve your spraying system, we provide a comprehensive 2 Quart Remote Pressure Pot for Capspray HVLP Turbines Parts List that includes genuine parts. To maintain your HVLP turbine system operating at peak efficiency, search our inventory today for the parts you require!

The 2 Quart Remote Pressure Pot for Capspray HVLP Turbines is a dependable material delivery system designed for professional finishers who require steady flow, reduced refilling, and superior spray consistency. By moving the paint supply away from the spray gun, this remote pressure pot minimizes hand fatigue while ensuring continuous material pressure throughout extended spraying sessions.

Engineered for compatibility with Capspray HVLP turbine systems, the pressure pot supports clean atomization and smooth finishes across a wide range of coatings. Its serviceable design allows easy maintenance and part replacement, making it a long-term, cost-effective solution for professional workshops and job sites. The availability of components through the 2 Quart Remote Pressure Pot for Capspray HVLP Turbines Parts List further enhances its reliability and service life.

Common replacement parts include cup gaskets, fluid tubes, air tubes, filters, fittings, and pressure seals. These components are listed individually in the 2 Quart Remote Pressure Pot for Capspray HVLP Turbines Parts List for easy identification and servicing.

Inconsistent flow is usually caused by clogged fluid tubes, worn gaskets, damaged fittings, or incorrect pressure settings. Inspecting and replacing worn parts restores proper material delivery.

Signs include air leaks, material seepage around the lid, loss of pressure, or uneven spray patterns. Replacing worn seals helps maintain stable pressure and prevents material waste.

Yes. Dried paint or debris inside the fluid tube or filter can restrict flow, causing sputtering or poor atomization. Regular cleaning and timely replacement of filters prevent these issues.

In most cases, replacing individual components is sufficient and cost-effective. The modular design supported by the 2 Quart Remote Pressure Pot for Capspray HVLP Turbines Parts List allows targeted repairs without replacing the full unit.