Subcategories

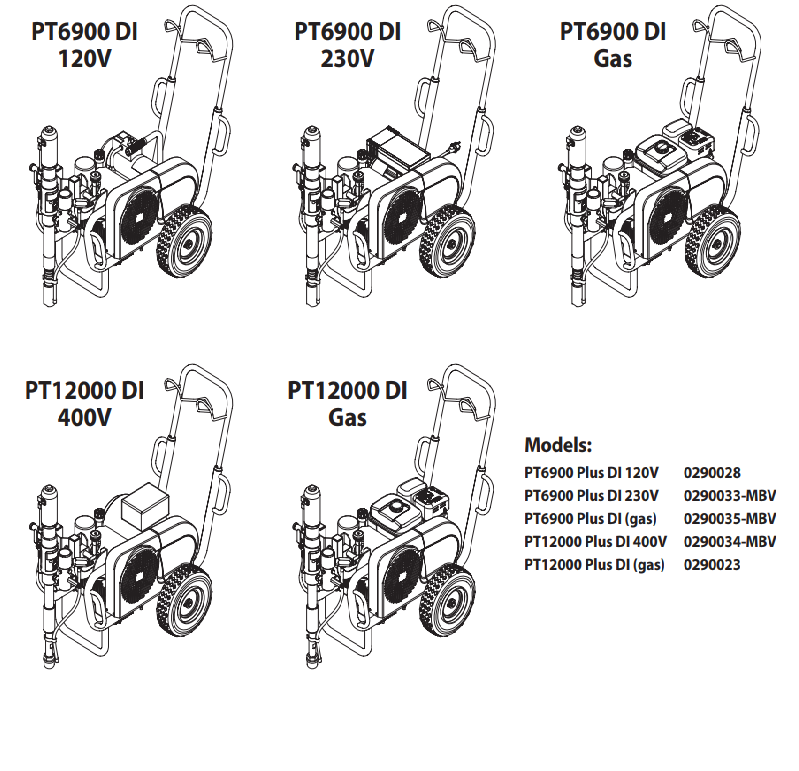

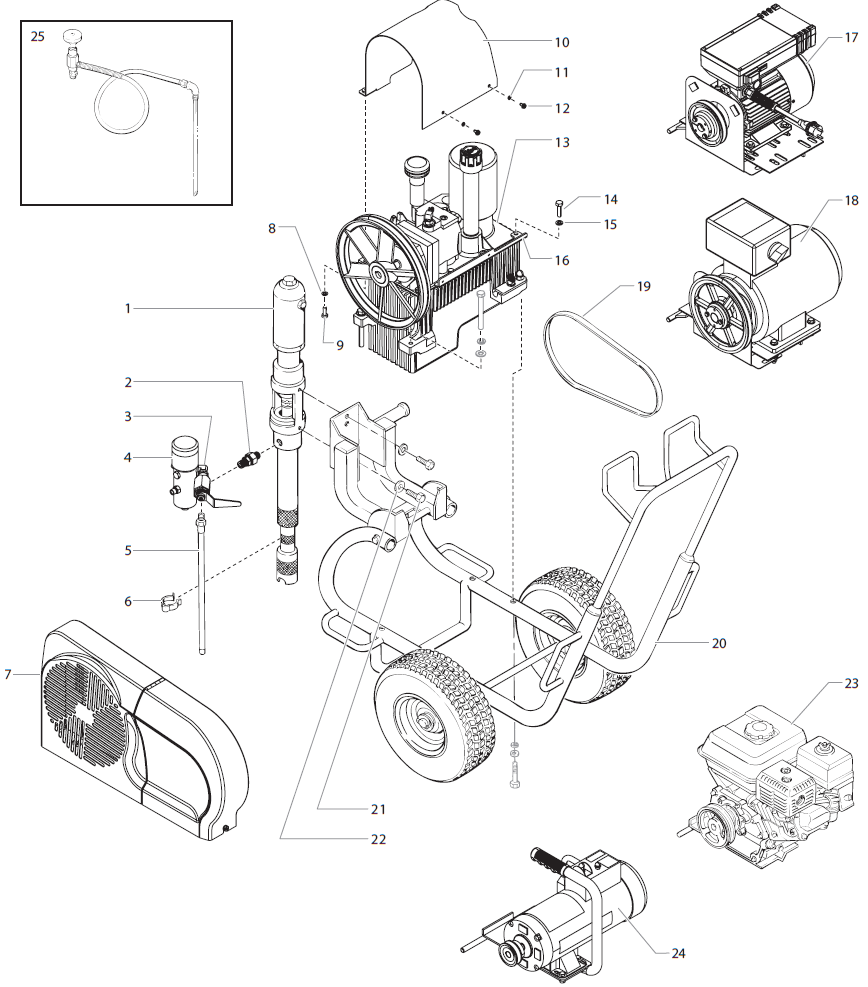

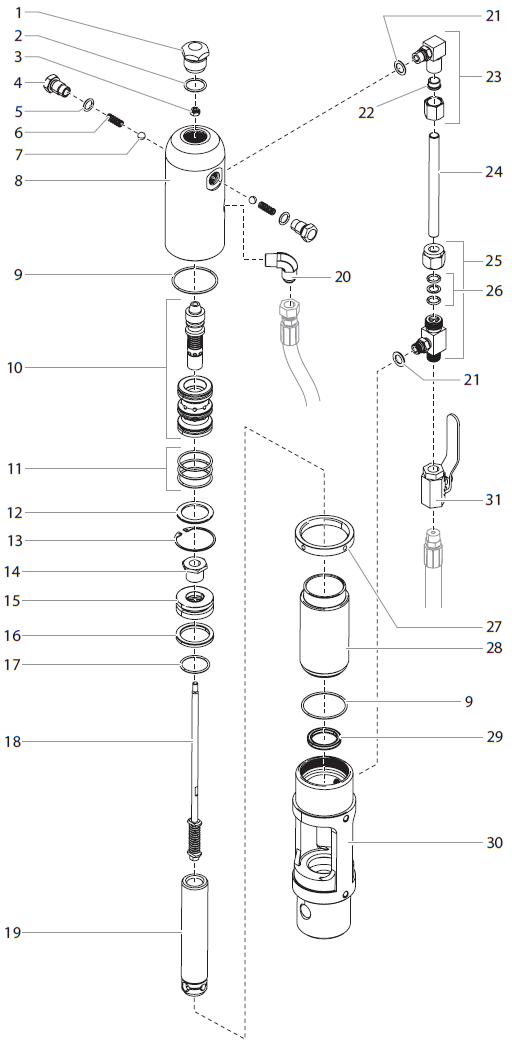

PowrTwin 12000 Plus DI Main Assembly Parts

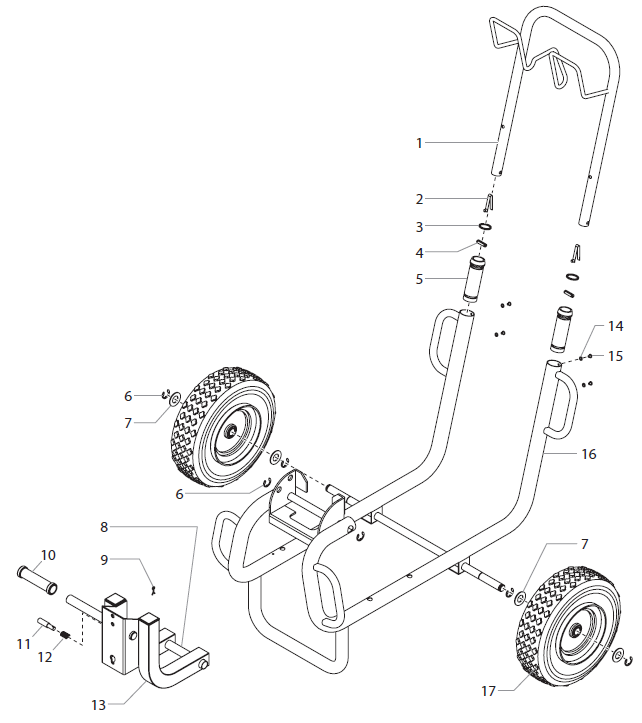

PowrTwin 12000 Plus DI Cart Assembly Parts

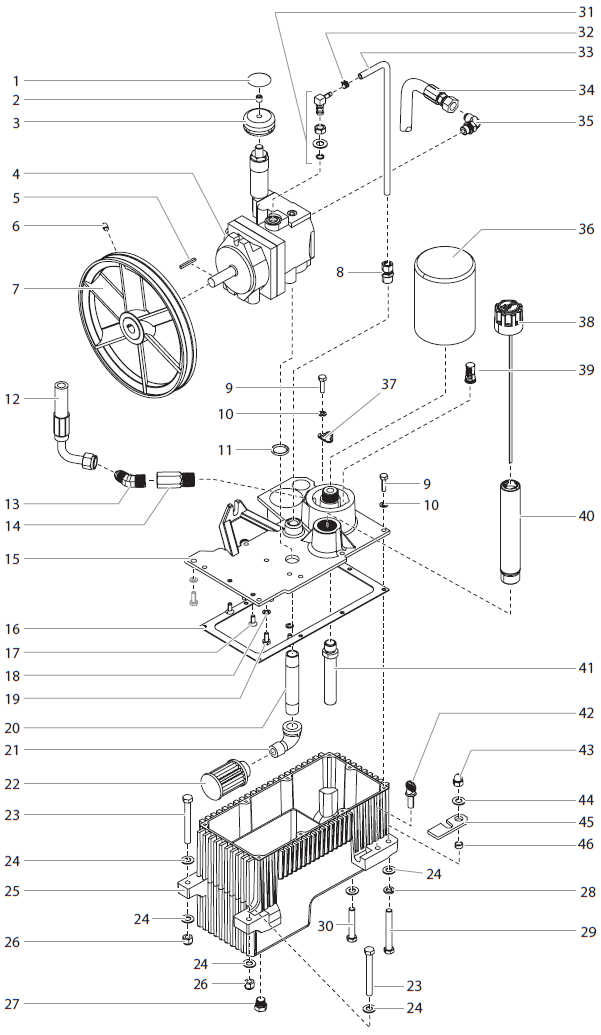

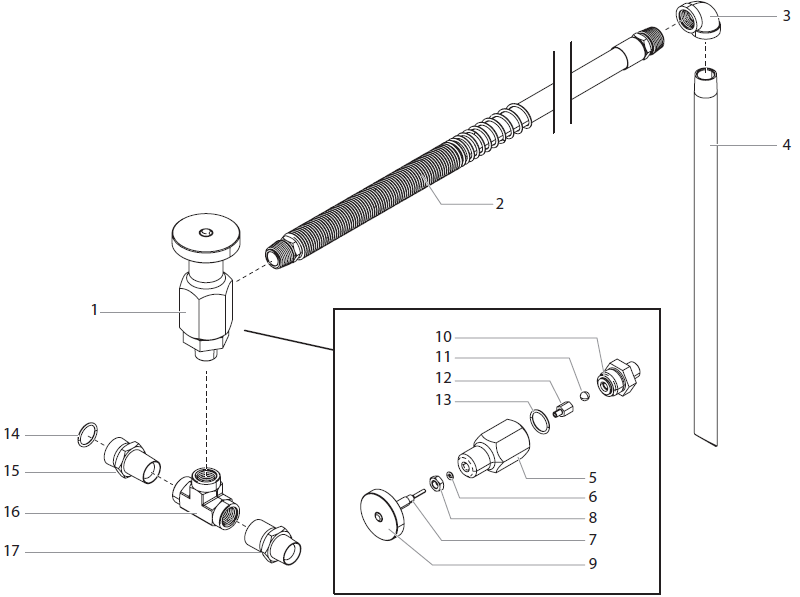

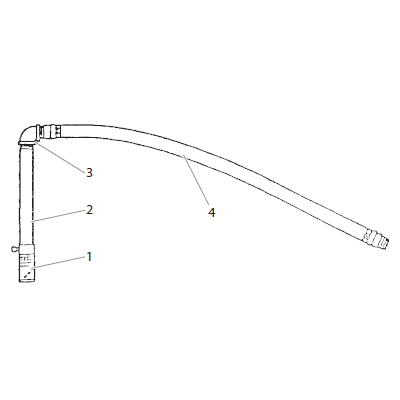

PowrTwin 12000 Plus DI Hydraulic System Parts

PowrTwin 12000 Plus DI Hydraulic Motor Parts

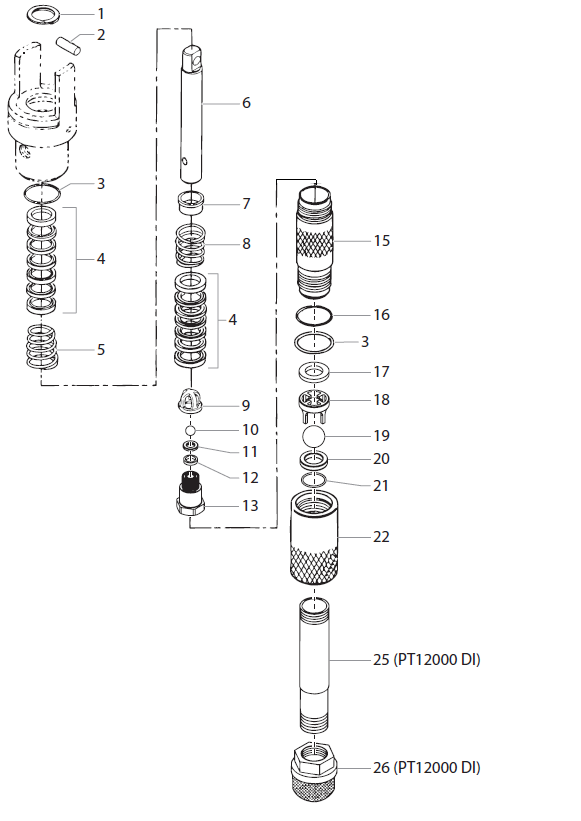

PowrTwin 12000 Plus DI Fluid Section Parts

.png)

PowrTwin 12000 Plus DI DC Electric Convertokit (400V) Parts

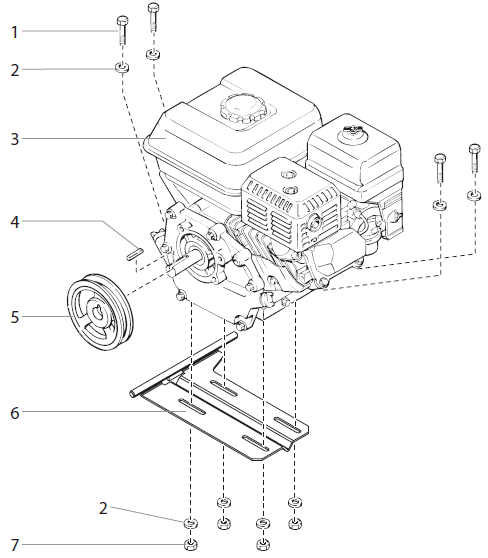

PowrTwin 12000 Plus DI Gas Convertokit Parts

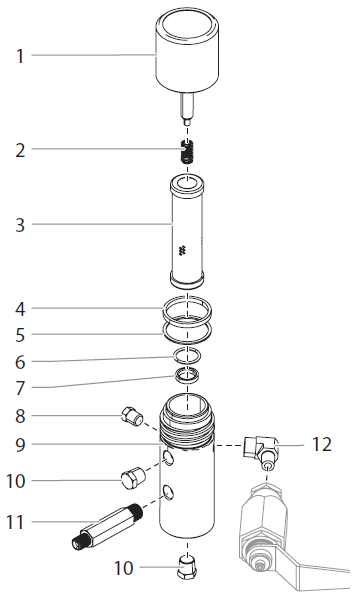

PowrTwin 12000 Plus DI High Pressure Filter Parts

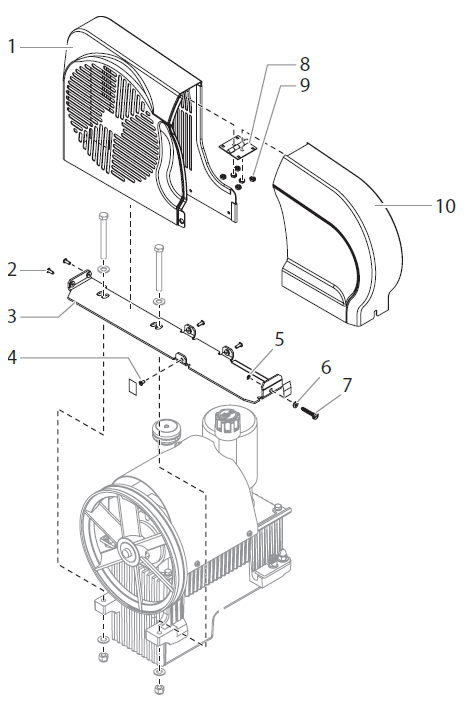

PowrTwin 12000 Plus DI Belt Guard Assembly Parts

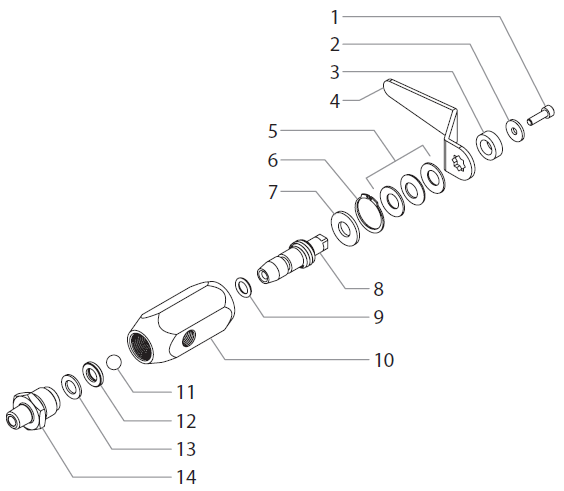

PowrTwin 12000 Plus DI Bleed Valve Assembly Parts

PowrTwin 12000 Plus DI Bleed Valve Assembly Heavy Materials Parts

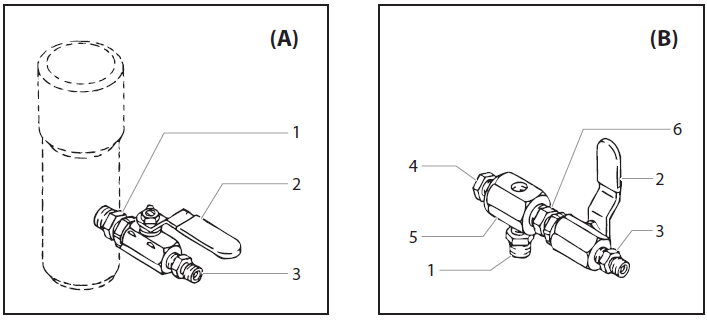

PowrTwin 12000 Plus DI Gun Manifold Assemblies(Optional) Parts

PowrTwin 12000 Plus DI Accessories Parts

NEW PRODUCTS FOR JANUARY - POWRTWIN 12000 PLUS DI

The PowrTwin 12000 Plus DI is a high-output hydraulic sprayer with a direct-immersion pump for maximum performance. It is designed for the biggest industrial and commercial applications where strong flow and nonstop reliability are essential.

If your sprayer begins to show signs of inconsistent pressure, abnormal vibration, or difficulty starting, it often indicates wear within the PowrTwin 12000 Plus DI Assembly Parts. These components are responsible for transferring power efficiently, and any grinding noise or hesitation in performance is a strong sign that internal drive gears or bearings may need replacing. Regular inspection helps prevent major downtime and ensures smooth operation.

When your sprayer cannot maintain consistent pressure, the issue commonly lies within worn or damaged PowrTwin 12000 Plus DI Fluid Section Parts. Check for worn packings, a leaking piston, or clogged valves. These parts take the highest workload, so even small cracks or seal failures can disrupt paint flow. Replacing faulty fluid section components restores proper pressure and eliminates pulsation during spraying.

A loss of power can occur when certain PowrTwin 12000 Plus DI Gas Engine Parts begin to fail, such as the carburetor, spark plug, or air filter. Even if the engine starts normally, reduced airflow or insufficient fuel delivery can weaken overall output.

Cleaning or replacing these engine parts often resolves performance drops and ensures the sprayer receives consistent power for demanding jobs.

Unusual noise from the belt area often points to worn PowrTwin 12000 Plus DI Belt Guard Assembly Parts or misaligned belts. If the guard is loose, cracked, or rubbing against the belt, it can create a scraping or rattling sound.

Ensuring proper alignment and replacing damaged guard components prevents belt slipping and protects the drive system from premature wear.

A belt should be replaced as soon as you notice fraying, glazing, or tension loss during operation. Because the belt works closely with the PowrTwin 12000 Plus DI Drive Assembly Parts and Belt Guard Assembly Parts, any wear reduces overall efficiency and may cause overheating. Timely replacement keeps the sprayer running smoothly and prevents stress on the drive components.